Top 10 tips to fight inflation in Procurement

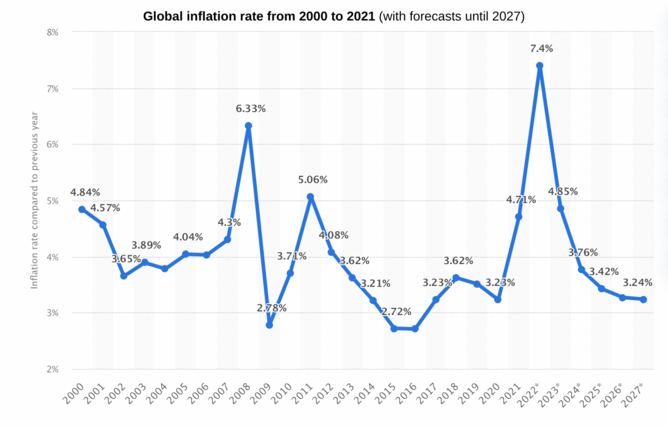

A series of compounding issues such as rising energy and food prices, fiscal instability in the wake of the pandemic and consumer insecurity, have created a new global recession, and it is believed that global inflation in 2022 will reach 7.4 percent, according to Statista. This is the highest annual increase in inflation since 1996.

As with all statistics, the rate is not evenly distributed, and can skew in either direction, according to which resources are being calculated.

Liquid energy fuel prices have hit inflation rates as high as 78.9% as of August 2022, (relative to Jan 2019) according top the same source.

As prices continue in their unstable rise procurement finds itself in a quagmire, but there are actions that your organisation can take to help counterbalance the turmoil. Here are ten tips to help drive prices down.

10. Identify costs on a systematic level

This category could be seen in the context of digitisation, as the latter will allow for easier discernment, however taken on its own, cost-identification can allow procurement organisations to offset huge potentially superficial losses.

Why superficial? Let's say that your organisation is so positioned that it's taking an indirect 10% inflationary hit from associated costs - relating to some volatile resource or other. And let's now say, that as an individual might do, you sit down and run a systematic cost-analysis of your business - that which the individual would see as personal budgeting.

You discover that actually, your business is spending 10% of its budget on something which isn't actually necessary for its operations, so you change it. You've just counteracted the 10% inflationary impact on your profit account.

Identify your costs - and do it properly. You may want to digitise to make this easier.

9. Think long-term

The most detrimental impact of inflation on procurement came about not because it wasn't able to prevent it, but that it wasn't able to predict it.

If the incoming inflationary period was forecasted, then the necessary measures would have already been in place, and the impact mitigated.

Predictive and responsive models will always yield more successful outcomes. It's not enough to be trying to keep afloat in choppy waters, but to be able to see the next incoming waves. Procurement functions need to always be fixed on the future and an algorithmic element should always be present in the organisation.

Short-term thinking is bound up with high more risk because it leaves the organisation unprepared for potential scenarios.

Every aspect of the procurement function, needs to have models incportaed into its workings, so that it can adapt under any circumstances, and must be oriented to the long-term.

8. Build supplier relationships

Not all suppliers are built the same. Business ethos is as varied as supplier numbers, and this is a question of quality over quantity.

Quality suppliers, are those who have enough expertise and vision that they recognise market forces as now being integral to their own operations and will adapt their strategic roadmaps accordingly.

Triple bottom lines are more extensive than you think. Work with suppliers who have the know-how to remodel their operations according to the environment and to work with you on newly established terms - as the market requires.

Further, do not confine yourself to a fixed-set of suppliers.

There are many local suppliers who can provide great services and perhaps even outdo your time-honoured set, so explore the terrain and build new relationships.

7. Internal risk mitigation

The key to internal mitigation is developing flexibility in product/service development or manufacturing.

Flexibility lets companies switch to things like cheaper raw materials when prices rise or shift production to different geographic locations that have cost or strategic advantages.

Companies can also stockpile raw materials associated with their business when prices are low and draw on these when prices spike. There are of course, costs associated with maintaining high inventory volumes, these costs may be justified by the benefits when raw-material prices are highly volatile.

6. Understand the difference between costs and investment

Not every spend is a cost. Investments are those spends which have an associated return, hence 'ROI'. Many procurement organisations assume that all costs are equivalent in that they are all part of the business in one form or another.

This is a huge mistake in thinking. Understand your costs and spends in terms of their associated ROIs, and actively push to put more of your organisations money into those which yield returns and increase your revenue and ultimately your profits.

5. Procure people

You've heard the term 'work smarter, not harder'. This applies to procurement organisations, and especially in times of inflation and economic uncertainty and instability.

Long hours of work do not necessarily translate into productivity. Granted, digitisation is absolutely key for procurement organisations - as it is with many organisations in the modern world - but do not overlook the people in the organisation in terms of effectiveness either.

People add value to procurement, and procuring the right people can have huge cost-saving benefits to your organisation as a whole.

4. Financial risk strategy: Hedge your bets

Forecasts and financial models determine whether your assumptions about future price changes still hold true and the impact that price rises would have on your business.

In the midst of inflationary pressures this may seem too little too late, but do not presume this to be the case.

The markets are still unstable and it's important that your procurement function understands that it is ever-evolving.

Financial risk strategies should be an ongoing component of your business' operations, and the closer you can get to real-time adaptations in your modelling, the better you will fare in a hiugh-inflaitonary period such as ours.

3. Use effective CRMs

CRM software helps procurement executives better-set priorities, allocate resources, and react to changing market conditions.

Through a systematic approach that evaluates sub-tier networks, companies can determine how their suppliers contribute to their success and develop ways to improve their performance.

Many industry leaders predict that CRM solutions will shift from standardised platforms to specific, bespoke solutions.

Organisations will create and measure KPIs that track their unique progress and procurement focus.

2. Invest in the right technology

There are many technologies that can help offset price fluctuations and the more advanced the tech, the more effective it will be in helping being costs down.

But not all procurement organisations are alike, and not all technologies will fit-the-bill when it comes to what they are trying to achieve.

Your organisation should understand what technologies will be directly applicable to its functions and invest in the right tech to achieve organisational outcomes.

Some of the technologies used by procurement that have reached their maturation stages are things like, cognitive computing and artificial intelligence, Intelligent content extraction, visualisation technologies, collaboration networks, predictive and advanced analytics. Invest in the correct tech for the correct job.

1. Digitise, digitise, digitise

The many cogs and gears that constitute the ticking clocks of procurement make for an environment of complexity.

Old-thinking in procurement held that digitising processes were optional recourses, and dusty-thinking even viewed it as a cost-burden.

Digitisation has, on the contrary - as shown time and time again - many associated cost-benefits, as well as others such as increased compliance security and the elimination of errors.

Here though, digitising will mean a real potential to drive costs down.

Digitise, and see the bigger picture.