Technology, IoT and risk management in procurement strategy

As reports of rising tensions between China and Taiwan hit the headlines, procurement professionals are once again preparing to tackle disruptions within the supply chain. Similarly to the Russian invasion of Ukraine, this eastern-based conflict is expected to have a huge impact on the global trade ecosystem.

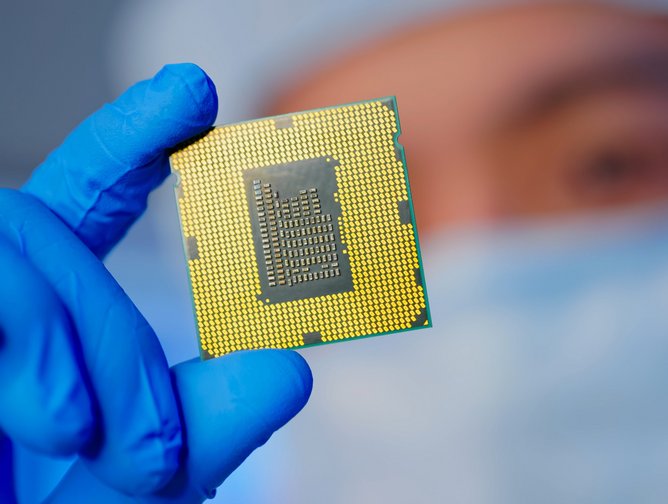

Taiwan is one of the world’s top technology manufacturers, leading the way in smartphone and semiconductor (chip) production. With China conducting military drills around the island, there's a high risk of a blockade that would put high tech supply chains under even more strain than they already are.

“There is certainly a threat there, and it would be ridiculous if western politicians and western manufacturers weren't actually cognisant of that and weren't flexing their supply chains to take that into account. China is sending a very clear message, and that could result in more disruptions in supply chains”, said John Manners-Bell, Chief Executive of Transport Intelligence in the UK and Founder of the Foundation for Future Supply Chain, in discussion with Supply Management.

The ongoing global semiconductor shortage

As soon as the COVID-19 pandemic broke out, the global manufacturing industry was put on hold. Since then, the supply chain has struggled against rising prices and growing shortages that have continually disrupted the flow of trade.

The global chip shortage has had a profound impact on the supply chain, especially in the tech and automobile industries. With Taiwan as one of the main suppliers of chips, conflict with China would mean another crisis in the supply chain – one that procurement professionals must begin to prepare for as soon as possible.

“Taiwan is fundamental in the semiconductor industry, and any sort of blockade of Taiwan has the potential for a massive impact on semiconductor supply chains and other high tech supply chains as well” added Manners-Bell.

As well as having to carefully manage risk in financial and logistical outcomes, procurement professionals are also being forced to consider the political and security implications of their partnership decisions amidst various geopolitical tensions.

One possible technique to be adopted by procurement teams is ‘friendshoring’, a process that is set to follow the offshoring and reshoring trends of the pre- and post-pandemic era. As the name suggests, friendshoring fosters links between businesses and governments with shared values.

The role of procurement professionals and technology in responding to global events

Research undertaken by Gartner revealed that 75% of procurement leaders have already considered shifting their partnerships away from China, due to the rising political tensions.

“Supply chain leaders have been modifying networks in a number of ways, be it with expansions, consolidations or simply modifications to buffers – which are more reversible than footprint decisions” said Kamala Raman, Vice President of the Gartner Supply Chain Practice.

“In order to respond to a dynamic landscape, procurement leaders must put in place diversified strategies for sourcing that balance global, regional or local suppliers in an ecosystem that optimises cost against the need for resilience.”

Alongside the challenges that come with rising prices and supply shortages, ongoing geopolitical conflicts mean that it’s becoming more important for procurement teams to invest in careful and efficient supply chain management. Ultimately, this depends on companies’ adoption of new technologies within a digitalised supply chain.

The digital supply chain has been emerging for a considerable time, with some companies (like AspenTech) already making efficient use of artificial intelligence (AI) and machine learning (ML) to analyse predictive-demand data.

The Internet of Things (IoT) also has an important part to play in the collection and processing of supply chain data. As procurement leaders are forced to shift their focus from reducing costs and enhancing productivity to building resilience and improving flexibility, IoT eases pressure by helping them to manage risk digitally. For example, IoT provides increased visibility on the movement of vehicles, equipment and devices along the supply chain, which means companies can track any disruptions and minimise their impact.

The unpredictability of the global market has always paralleled geopolitical as well as economic factors. But it seems that, now more than ever, procurement requires a flexible approach, in order to deal with disruptions and overcome instabilities within the supply chain.