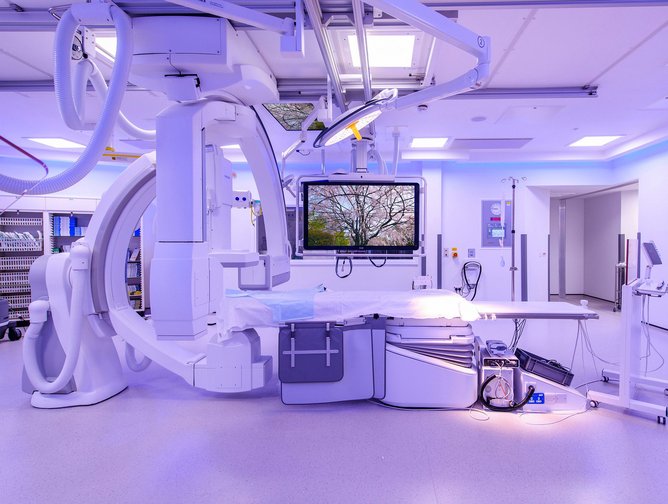

There can be few better opportunities to learn about your products and your customers than seeing them in action in the hospital or clinic. Scott Schwartz from Philips recently had that opportunity at a hospital appointment, where he saw the global health technology company’s ultrasound systems being used first hand. As Chief Procurement Officer and Head of Sustaining Engineering at Royal Philips, he knows all too well how important their products are to people all over the world.

"The beauty of what we do here is that we make products and solutions which have a direct connection to our family and friends. Our products help them and other people around the globe improve or save their lives. That’s really inspiring and has motivated me throughout my career in medtech,” says Scott Schwartz, who has been recently appointed as Chief Procurement Officer at Philips, in addition to his Sustaining Engineering Lead responsibility. “We help improve the workflows in hospitals, lower the cost of care and have a direct impact on society. That greatly contributes to my job satisfaction: it's all about helping people and improving their life and wellbeing. At some point of our life, we are exposed to our own products either ourselves or our family members, friends or colleagues are. That makes our task very real and puts a face to it.”

This purpose driven motivation is what Scott also likes to drive into his own team. He was able to build a purpose-driven high-performance team that understands the impact Philips’ products and solutions have on the end user. Driving strategic ideation into a strong rigor in execution is a valuable mantra for success.

“The key here is that, first, you have really talented creative people that are always curious to dig deeper, to dig for more – and I think that's the culture that we are trying to create here, that rigor, that depth, that curiosity to find more,” he says. “That is the foundation of trying to find these improvement ideas.”

Scott is very clear on the importance of talent in his own team, but for him, the team doesn’t end at the walls of Philips. He recognized in past company experiences how important it is to team up with strategic partners in the value chain to do things first time right and avoid higher costs in later product life cycle stages. It is therefore important for Philips to share their purpose as well with their strategic suppliers and connect them to the outcomes desired for the customers and patients.

“I think it's really valuable to hear different users talk about your products,” he says. “A lot of times, what you believe they're going to say is not actually what they end up saying. For me, it was really insightful to talk to the technician because you are thinking they are going to talk a lot about the actual diagnostics, the clarity of the imagery and the quickness of the machine, which are things we are driving at the company. But instead, a lot of times you end up hearing about the basic ergonomics and usability of the machine. It's important to see that there is more to the overall satisfaction of the customer than just the traditional features you are driving.”

Scott explains that having the customer’s point-of-view helps in ensuring that they are providing market-leading technology that makes a tangible difference to the lives of both patients as well as the healthcare professionals using the equipment.

“We're making these products to help people; real people and real faces are using our products. So that purpose, that responsibility, is constantly reinforced in the organisation and I'm trying to continually implement this outside-in view in the organisation. We want everybody thinking outside-in. What does this product do, and as I understand what it does, how do I improve that?”

The sector comes with a degree of public responsibility, and, as someone who has worked in medtech for the vast majority of their career, Scott says it is something with which you foster a deep connection.

“I wouldn't go anywhere else or to any other sector because the beauty of what we do here is that we make products and solutions which have a direct connection to our family and friends.” Scott’s route to Philips has taken him across different business roles since completing a mechanical engineering degree at MIT. The first career step was to 3M Company after graduating. He completed a master’s degree in mechanical engineering and an MBA at the University of Minnesota. Scott says that his goal was always to be a leader of technical people, so he needed to be sure his technical capability was strong to have credibility in an engineering environment, but also having the MBA to bring a broader business view to the table. He then spent eighteen years at Boston Scientific working across product development and supplier engineering, providing him a wide scope of experience to manage products from end-to-end during their development.

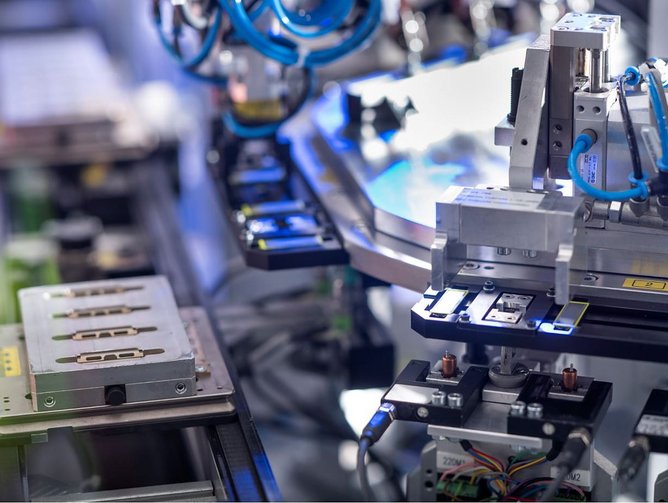

Scott believes the structure at Philips Procurement and Sustaining Engineering is one of their key strengths as it allows them to have more of an end-to-end overview of products, from inception to delivery. As well as the traditional procurement responsibilities that fall under his responsibility, there is also an engineering arm connected directly to procurement, which allows them to drive the overall strategy through partnerships with their supplier base.

“It’s a unique combination compared to most other procurement organisations that you would typically see,” he says. “We are also heavily involved in new product development – which I think is common with other procurement organisations – but we are doing it at an even more technical level, partnering with the R&D organisation and getting involved very early in that new product innovation cycle.”

This set up allows Philips to accelerate the strategic execution and drive strategic initiatives from the Procurement perspective, whether that is supply base mobilisation, innovation, cost down and quality up activities. Projects focused on quality, productivity, resilience, or innovation can be driven with great speed in partnership with the supply base. This makes supplier performance management truly end to end. It is much faster and more efficient to have the needed resources in one team. By having the internal team joining forces with strategic suppliers Scott aims to foster a culture of collaborative disruption to drive into fast, customer-oriented outcomes.

Scott has been at Philips through a time of transformation, as it pivoted further into a health technology company, which now is one of the world’s largest health technology companies. It has been a long journey for a company that started in 1891 with its namesake, Frederik Philips and his son Gerard, producing electrical lighting products in an Eindhoven factory before diversifying into home appliances.

“When I first arrived at Philips, it was basically a conglomerate with a healthcare technology business, the heritage lighting business, personal health and a domestic appliances business. Over those eight years, we've actually transformed pretty impressively in such a short time into a truly health technology company – so, spinning off our lighting business, divesting our domestic appliance business and then creating one of the largest health technology companies in the world.”

“The industry needs to transform from working on hardware alone to driving cost reductions, simplicity in workflow, and improved outcomes for patients. To achieve those ambitious goals, you have to bundle technologies, bring hardware and software together to create solutions that truly solve problems. This requires the procurement organisation to transform as well. It is not about hardware alone anymore. It is about bringing in suppliers that help with the innovation on those solutions which is easier to say but not so easy to be done. Driving innovation on hardware is a little bit more concrete than driving ideation on a solution that is not easy to conceptualise and requires a lot of pieces to be put together and that is the challenge we face: how do you bundle solutions that truly improve outcomes, reduce costs and improve the workflow in clinics and hospitals?”

A vital part of that transformation has been the relationship Philips has with their partners and suppliers, which Scott and his colleagues are leveraging to deliver more solutions that improve outcomes, reduce costs, and optimise workflows in clinics and hospitals.

“Having a strong partnership with our suppliers is crucial, allowing us to connect the suppliers to our problems, thus connecting the supplier innovation capabilities to our problems, to actually leverage a much broader ecosystem to identify these step-up improvements.”

By using an early engagement approach with their suppliers, Scott believes it gives them the best possible chance of delivering solutions and step-up improvements to their products, and, with his role having a larger overview of development, it can bring the best out of those partnerships.

“Everybody thinks that every procurement leader says, ‘We are going to leverage the supplier ecosystem and bring the suppliers closer to our activity’. It’s easy to talk about the concept, but it's very hard to do in practice. We have done some of the structural things, like consolidating our supply base to strategic suppliers that have strategies and visions lined up with Philips’ strategy and vision. I think that it is key to have these smaller sets of suppliers that are more strategic as we interact with them.”

It is this culture of trusted collaborations embedded in these partnerships that allows a stronger bond between the two for the benefit of both parties, and, ultimately, for the customers and patients who use the technology. Scott is confident that the company’s top strategic partners feel listened to and empowered to play an active role in the process of product development.

“That's the key – that it’s a two-way street,” he says. “They are partners and so we have confidence in them, but it's also our responsibility to treat them like strategic partners and give them benefits for being our strategic partners. Whether that is access to our new product development opportunities or focusing on other creative innovations that we are working on, we want them to feel part of Philips.”

Scott also says that they strive to make sure there is a flow of communication and innovation coming from their suppliers for productivity, quality, performance, and resilience. That is the benefit of connecting a strong procurement organisation with a sustaining engineering capability to drive execution.

All those ideas permeate through product development cycle to the consulting rooms, clinics and wards of hospitals and clinics around the world. It was following his appointment that Scott got to witness the benefits of that approach first hand and see staff interacting with their innovations.

‘It was just very insightful to talk to the technician and ask him about Philips and our products – that is what it's all about. Not only the connectivity to the personal experience you have with our products, but also seeing that our products are perceived as delivering on their high-quality premise. And that's satisfying as well.”