What is Pepsico’s Sustainable Sourcing Programme?

The aim of the project since conception has been to work with the procurement, sourcing and supply chain partners, and use their purchasing power as a global company to raise standards.

The company identifies that in their mission statement for the wider project, saying that using their influence they can work with suppliers to meet best practice standards and comply with local regulations. They also believe an effective sustainable sourcing program should raise standards of human rights, labour, environmental management and conservation of natural resources.

SSP Approach

Their Positive Agriculture ambition aims to embed integrity, fairness and stewardship throughout the Pepsico agricultural supply chain. As a result of this, they expect suppliers to adhere to the same standards of integrity to which they hold ourselves. All suppliers, vendors, contractors, consultants, agents and other providers of goods and services who do business with or on behalf of PepsiCo entities worldwide are expected to follow their supplier code of conduct and all other relevant policies as a condition of doing business.

The ambition is organised through four key verticals:

Sustainable Sourcing Program (SSP) - A supplier engagement program for their most business-critical first-tier suppliers and business partners that includes formal risk assessments, third-party audits, corrective action and capability building.

Sustainable Farming Program (SFP) - A farm-level continuous improvement program that helps us assess our direct growers, identify potential gaps relative to our policies, implement plans to safeguard human rights and embed regenerative agricultural practices.

Procurement practices - Supply contracts include their code of conduct, for which Pepsico provides training through the SSP and on their website. In purchasing categories with time-bound commitments to sustainable sourcing, such as palm oil, procurement teams use tools such as supplier scorecards to evaluate and compare performance of individual suppliers against company expectations.

Tailored programmes - In cases where the company identifies potentially high risk or priority supply chain concerns, they deploy specific programs to improve knowledge, awareness and outcomes.

What progress has been made?

In 2022, 902 on-site audits or virtual assessments were conducted with first-tier suppliers using the industry standard assessments. After the on-site audits were completed, sites were scored from red to green based on the severity and number of instances of non-compliance found on-site.

Among their Tier 1 strategic suppliers in 2022, the non-conformance rate for suppliers with a ‘red audit’ high risk result was 7% of their total assessments and at the year-end corrective action plans had been developed for 100% of these red sites which are validated by an auditor at their next on-site follow-up audit.

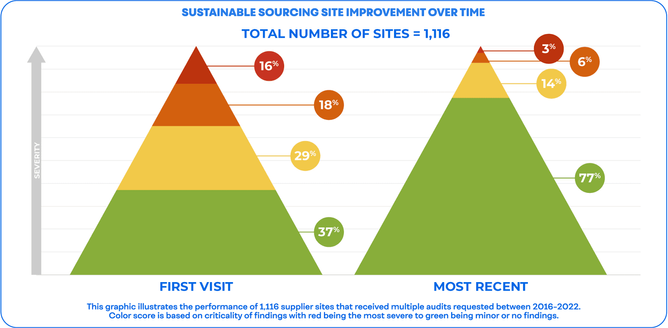

Since the SSP launched in 2015, Pepsico say they have seen strong improvement from sites as they learn from audit findings, strengthen their internal management systems and capabilities and resolve non-compliances.

What are the current priorities?

The programme continues to evolve over time, and the company published five key focus areas for 2023.

- Expanding the risk-based focus of their program to support further engagement with business-critical and potentially high-risk areas in the supply chain through continued engagement in multi-stakeholder initiatives.

- Extending the principles of Pepsico’s Supplier Code of Conduct to more franchisees and joint venture partners.

- Deepening the specificity of their program tools to assess and address risks in upstream supply chains, including responsible recruitment with temporary labour agents by trialling different assessment technologies like worker voice.

- Continuing to analyse multi-year supplier performance to better understand trends in supplier challenges, root causes of recurring noncompliance and to further evaluate the effectiveness and efficiency of engagements.

- Improving Pepsico’s ability to provide suppliers with targeted training and capability building opportunities based on the challenges identified through their assessments and audit results.

*************************************************

For more insights into Procurement & Supply Chain - check out the latest edition of Procurement Magazine and be sure to follow us on LinkedIn & Twitter

Other magazines that may be of interest - Supply Chain Magazine | Sustainability Magazine

*********************************************

BizClik is a global provider of B2B digital media platforms that cover 'Executive Communities' for CEOs, CFOs, CMOs, Sustainability Leaders, Procurement & Supply Chain Leaders, Technology & AI Leaders, Cyber Leaders, FinTech & InsurTech Leaders as well as covering industries such as Manufacturing, Mining, Energy, EV, Construction, Healthcare + Food & Drink.

BizClik, based in London, Dubai & New York offers services such as Content Creation, Advertising & Sponsorship Solutions, Webinars & Events.