Three key insights: GEP Global Volatility Index November 23

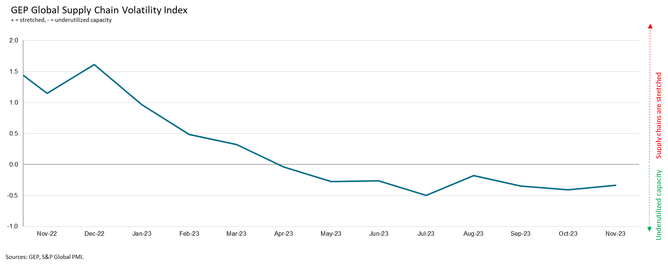

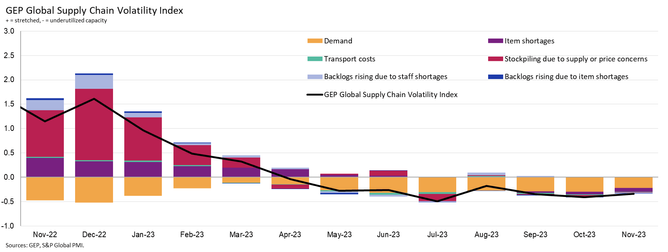

The index is a leading indicator for procurement and supply chain professionals regarding conditions, shortages, transportation costs, inventories and backlogs based on a monthly survey of 27,000 businesses. The GEP Global Supply Chain Volatility Index was once again in negative territory at -0.34 in November, compared to -0.41 in October, indicating an eighth successive month of spare capacity across global supply chains.

“This persistent, month-after-month, excess vendor capacity means that the end to the global manufacturing recession is still some way off,” explained Todd Bremer, vice president, consulting, GEP. “North America continues to buck the global economic headwinds. Continuing excess supplier capacity in Asia gives manufacturers greater leverage to drive down prices in 2024.”

Three insights

- Global producer capacity goes underutilised for an eighth successive month in November; supplier order books remain unfilled

- Inactivity across Asia’s supply chains bodes ill for near-term global manufacturing improvement

- Demand stays subdued, especially in Europe, where manufacturing is in a recession

In contrast, North America is displaying greater resistance to global economic drags as supplier spare capacity becomes less prevalent

Slump in demand in Europe

Weakness in demand for raw materials, components and commodities continued in November, although the global slump in purchasing activity did ease, primarily because of North America, which seems to be well past the peak of its manufacturing industry downturn. In fact, output and new orders at intermediate goods makers in the U.S. — which includes chemicals, metals, electronic components and electrical equipment manufacturers — improved in November.

On the other hand, Europe’s slump in demand remained severe, reflecting recessionary conditions. Capacity at Asia’s suppliers went underutilised to one of the greatest degrees in the post-pandemic era, boding ill for the near-term outlook of global manufacturing. Slight improvements in global item supply, easing transport cost pressures and destocking, as seen in GEP’s November data, provide additional evidence of continuing weakness across the global economy.

Five key November 2023 findings

DEMAND: Weakness in demand for raw materials, components and commodities persisted in November, although, encouragingly, the downturn was its softest since April. Regional data revealed less aggressive cuts to purchasing by North American and Asian companies, but the decline in input demand remained considerable in Europe.

INVENTORIES: Global businesses continue to demonstrate little appetite for building up their stocks, with inventory managers unwilling to hold surplus stock in warehouses.

MATERIAL SHORTAGES: Reports of item shortages fell again in November and remained at their lowest since January 2020.

LABOUR SHORTAGES: Reports of backlogs accumulated because of labour unavailability remain historically subdued, showing that production capacities are not constrained by staff supply.

TRANSPORTATION: Global transportation costs have stabilised and held close to the long-term average in November.

Key regional findings

- NORTH AMERICA: The index rose to -0.21, from -0.34, its highest level since April, and is now well below its low point of -0.85 in June, suggesting the manufacturing downturn has passed its peak in the U.S.

- EUROPE: The index rose to -0.85, from -0.90, but remains at a level consistent with significant economic weakness as recession looms for the continent.

- U.K.: A big increase in the index from -0.93 to -0.58 tentatively suggests the U.K.’s economy may fare better than some of its European peers, but the U.K.’s suppliers are still experiencing considerable spare capacity.

- ASIA: The index rose to -0.24, from -0.38. Nonetheless, this still highlighted one of the greatest degrees of vendor spare capacity in the post-pandemic era.

How does the GEP Global Supply Chain Volatility Index work?

The GEP Global Supply Chain Volatility Index is produced by S&P Global and GEP. It is derived from S&P Global’s PMI surveys and sent to 27,000 global companies. The headline figure is a weighted sum of six sub-indices derived from PMI data, PMI Comments Trackers and PMI Commodity Price & Supply Indicators compiled by S&P Global.

What do the values in the GEP Global Supply Chain Volatility Index mean?

A value above 0 indicates that supply chain capacity is being stretched and supply chain volatility is increasing. The further above 0, the greater the extent to which capacity is being stretched.

A value below 0 indicates that supply chain capacity is being underutilised, reducing supply chain volatility. The further below 0, the greater the extent to which capacity is being underutilised.

The index is published once a month and you can review previous studies here.

*************************************************

For more insights into Procurement & Supply Chain - check out the latest edition of Procurement Magazine and be sure to follow us on LinkedIn & Twitter

Other magazines that may be of interest - Supply Chain Magazine | Sustainability Magazine

*********************************************

BizClik is a global provider of B2B digital media platforms that cover 'Executive Communities' for CEOs, CFOs, CMOs, Sustainability Leaders, Procurement & Supply Chain Leaders, Technology & AI Leaders, Cyber Leaders, FinTech & InsurTech Leaders as well as covering industries such as Manufacturing, Mining, Energy, EV, Construction, Healthcare + Food & Drink.

BizClik, based in London, Dubai & New York offers services such as Content Creation, Advertising & Sponsorship Solutions, Webinars & Events.

- What is The White House's Sustainable Procurement Programme?Sustainability

- How SAP is Using AI to Transform Supply Chain SolutionsTechnology & AI

- Why ISG Provider Lens say GEP is a Global Procurement LeaderTechnology & AI

- Key Insights: GEP Global Volatility Index April 2024Supply Chain Management