8 ways the circular economy will transform business: WEF

"Imagine an economy where resources get used but not used up; new business strategies keep products, components and materials in the system – during and after use – and where dangerous, dirty waste is at an absolute minimum. You’ve just imagined the circular economy," - this is the opening paragraph of the latest World Economic forum (WEF) article on the circular economy.

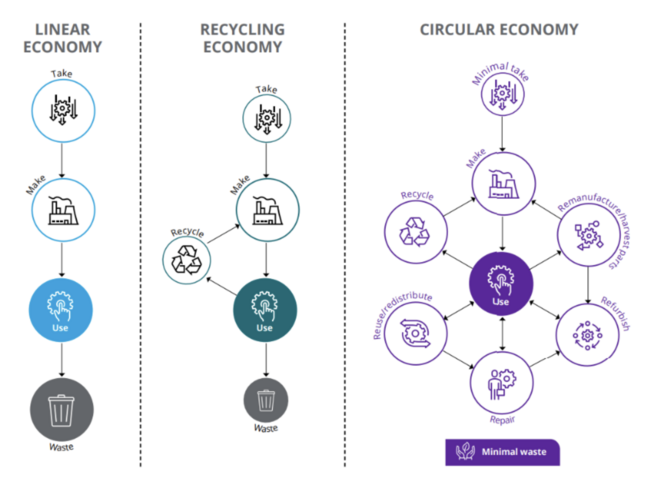

A circular economy is a system in which resources are kept in use for as long as possible, through reusing, repairing, refurbishing, and recycling products and materials.

In this way, the goal is to minimise waste and optimise the use of natural resources.

In a traditional linear economy, goods are produced, used, and then disposed of as waste. This model is not sustainable in the long run, as it relies on the constant extraction and consumption of finite natural resources.

A circular economy, on the other hand, aims to keep resources in use for as long as possible, reducing the need for constant resource extraction and diminishing waste production.

Procurement, defined at its most basic level as the process of acquiring goods and services, inevitably plays a critical role in realising a circular economy.

The article look at transitioning from a traditional to a circular economy and the advantages that such transition can provide.

Such a transition of course is in effect a disruption, and according to WEF, the phenomenon of disruption is not a new concept, as throughout history, innovative companies have challenged the established norms of their respective industries. One such example is the advent of "born-digital" start-ups, which disrupted pre-internet legacy organisations with traditional brick-and-mortar business models.

In a similar vein, the emergence of mass production and the advantages of railroads over steamships in the past resulted in the obsolescence of smaller, local manufacturing plants. The recent containerisation of global trade has only accelerated this trend.

Currently, the emergence of "born-circular" companies and their sustainable business models threatens to disrupt linear organisations and erode their market positions. However, as we have seen with the digital revolution, legacy businesses that adapt to the new paradigm of circularity will survive.

The shift towards circularity has garnered political support, as exemplified by the EU's commitment to transitioning to a circular economy for a cleaner and more competitive Europe. Customers are also demanding more sustainability, with predictions that by 2029, supply chains producing waste will be deemed unacceptable by both consumers and governments. This transition is happening at an unprecedented pace, with circular business models being essential for competitiveness by as soon as 2030.

1. More attractive products

The connection between ESG claims and consumer behavior has been well established. A recent study by McKinsey and NielsenIQ confirmed that consumers are more likely to spend on sustainable products, show increased loyalty towards eco-friendly brands, and support their growth.

Meanwhile, the Wharton School of the University of Pennsylvania found that consumers who opt for sustainable products are motivated by a range of reasons, including improving the environment (30%), reducing production waste (23%), cutting their carbon footprint (22%), and addressing animal welfare concerns (17%).

Circular business models offer a novel approach to sustainable production by turning waste into an asset instead of a liability. By integrating renewable and recyclable inputs into the production process, these models can significantly reduce or eliminate waste, pollution, and biodiversity loss.

As a result, circular models can address the three key drivers of sustainable consumption, making eco-friendly products more appealing to consumers than ever before.

2. Greater customer intimacy

In the traditional linear economy, companies simply sell new products to the next customer in line and rarely have direct communication with end-consumers. However, in circular business models, maintaining a continuous dialogue throughout a product's lifetime is crucial.

This means providers must be willing to engage in ongoing discussions with customers at every touchpoint - from the initial sale to repairs, returns, and upgrades.

Circular organisations are taking things one step further by offering product-as-a-service, a model in which customers pay for the use of a product over a limited period of time. Providers maintain ownership of the product and are incentivised to ensure ongoing maintenance, durability, upgrades, and proper disposal at the end of its life cycle.

Additionally, the sharing economy is gaining traction by maximising the use of idle assets within communities, while offering affordable and convenient access to products and services. These circular business models, along with new recovery models, will create even more opportunities for customer touchpoints and engagement.

However, continuous end-consumer dialogues may be a new experience for many providers who need to learn how to make them relevant, timely, and engaging. This ongoing dialogue will help providers better understand customer usage patterns and perceptions, ultimately leading to improved products and services.

3. Lower costs

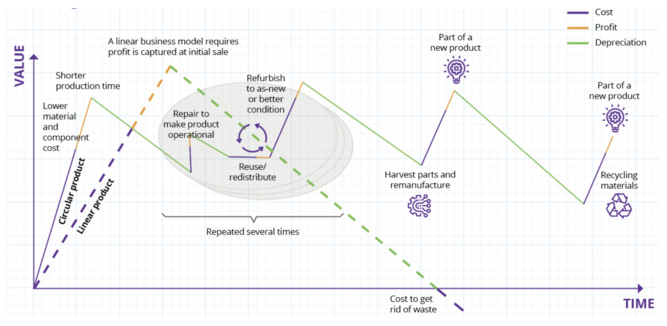

Circular products are not just a passing fad - they are designed to be used and reused, repaired and refurbished, and ultimately disassembled. And it's not just the products themselves that are circular, the components are too. This approach results in lower costs and more cost-effective services because the products are used for longer periods of time.

Take, for example, SKF, a bearings supplier based in Sweden, which now offers oil-as-a-service with its RecondOil offering. This innovative approach uses a double separation technology (DST) to remove even the smallest contaminants from oil, allowing it to be cleaned and reused. In the past, an industrial seven-year production cycle would require 30 oil changes, but with RecondOil, the same seven years can be completed with no additional oil or logistical costs, and no lost production time.

It's worth noting, however, that transitioning to a circular economy requires investment and courageous business decisions. While it may not provide cost reduction from day one, the benefits of circular business models are significant and long-lasting.

4. Recurrent income sources

Circular business models offer a new approach to generating income, not just through product-as-a-service or sharing-economy models, but also through the commerce of recovered components and materials. Each time these items are resold, they generate income, creating a recurrent revenue stream.

In addition, related services like repairs, redistribution and refurbishment also provide opportunities for generating recurrent income. Instead of treating waste and by-products as liabilities, circular businesses treat them as assets, finding ways to repurpose and extract value from them. With this approach, waste and by-products become sources of revenue, creating a more sustainable and profitable business model.

5. Greater resilience

Circular products are not just environmentally friendly but also financially beneficial for organisations. By designing products for recovery, organisations can retain control over their production inputs, ensuring a more stable and reliable supply chain.

When products reach the end of their life, embedded components, materials, energy, and other resources can be recovered and reused, reducing the need for expensive new inputs.

To encourage users to return products, companies can offer incentives such as deposit refunds or favorable terms in their product-as-a-service contracts.

By doing so, companies can create a reliable and sustainable source of recovered components and materials.

In addition, the use of circular business models can help organisations protect themselves against supply chain disruptions and price fluctuations. By recovering and recycling materials, companies can reduce their reliance on external suppliers and ensure that their costs remain stable and predictable.

6. Greater product and component utility

The traditional linear economy model revolves around product ownership, resulting in low utilisation rates, such as cars parked for 95% of the time. Conversely, product-as-a-service and sharing economy models increase utilisation, leading to higher income per unit.

In circular economy models, products are designed for reuse, repair, reconditioning, and upgrading, which significantly increases their utilisation.

Similarly, components are harvested and remanufactured, while materials are ultimately recycled, leading to even higher utilisation rates and greater economic efficiency.

7. Reduced production times

Circular economy models aim to reduce waste and increase resource efficiency. One way to achieve this is through refurbishing products and components that have stopped working, restoring them to a nearly new or as-new condition.

This eliminates the need to manufacture many new product components, reducing the overall demand for raw materials and energy.

The wind power industry is an excellent example of this principle in action. With demand for wind turbines skyrocketing, some manufacturers are experiencing production lead times of up to two years. By contrast, an existing wind turbine can be refurbished and delivered in just four months, reducing the need for new turbines and materials while maximising the value of existing assets.

8. Climate and environmentally friendly

Circular economy practices such as recycling, repairing, refurbishing, and reusing products have a lower environmental impact and require less energy than conventional methods.

This approach addresses various environmental issues, including biodiversity loss, deforestation, and mining, as well as the manufacturing and transportation of raw materials.

By adopting safe disposal methods, organisations can further reduce their environmental impact.

The amount of e-waste generated worldwide in 2019 was 53.6mn metric tons, and this number is predicted to rise to 74.7 megatons by 2030, according to the Global E-waste Monitor 2020.

To address this issue, several manufacturers, importers, and distributors have taken up the responsibility of managing electronics at the end of their life.

For example, n2s advocates for reuse as the primary method of waste management in line with the European Hierarchy of Waste Management. The company aims to reuse or redeploy devices first, with recycling reserved for those items that are beyond economic repair. In 2021, n2s recycled 149.489 tons of PCBs and 189.914 tons of electric cable, recovering 129 tons of copper. This approach is more sustainable as it saves between 12,900 and 20,640 tons of copper ore required for the same amount of pure copper through traditional mining.

In the face of ongoing changes, it is imperative that traditional "linear" organisations take action.

While it may be difficult for large-scale companies to depart from the linear processes that have enabled production and consumption for centuries, doing nothing is not an option.

To remain competitive beyond 2030, leaders must embrace circular business models, initiate pilot programs, and develop a strategy for transitioning to the circular economy, which will be the economy of the future.

- Three key takeaways: Responsible procurement AI use reportTechnology & AI

- Circularise forms alliance for circular economy in JapanSustainable Sourcing

- Alibaba & L’Oréal partner for circular economy in cosmeticsSustainable Sourcing

- The LASER Framework: Designing for the circular economyProcurement Strategy