Bain & Company: Closed-Loop PLM: Revolutionising Procurement

In today's fast-paced machinery industry, where innovation is the name of the game, companies are constantly seeking ways to gain a competitive edge.

One of the most promising avenues for achieving this is through closed-loop product life cycle management (PLM), a transformative approach that promises to revolutionise procurement processes, drive efficiency, and foster innovation across the sector.

The Rise of Closed-Loop PLM

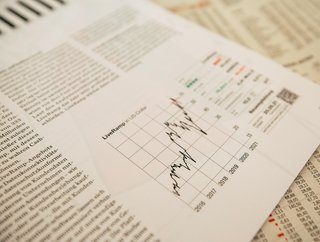

Recent research indicates a seismic shift in the machinery industry's approach to PLM, with a growing number of companies embracing closed-loop systems. According to Bain's Global Machinery & Equipment Report 2024, the adoption of closed-loop PLM has emerged as a strategic imperative, with leading companies reporting significant reductions in time to market.

Statistics paint a compelling picture of this trend, with over 70% of machinery customers expressing a desire for more personalised or customised products compared to three years ago. This evolving customer landscape has spurred machinery executives to prioritise closed-loop PLM, recognizing its potential to meet these heightened expectations while driving operational excellence.

Joshua Hinkel, Partner at Bain & Company, spoke during the company’s 2024 webinar on the report, he said: "In almost all industries, our linear business models and supply chains consume about 1.75 times the Earth's renewable resources annually, rising to nearly 5 times in developed countries.

"Despite decades of efforts, global circularity has remained stagnant at around 9 to 10%. The key challenge lies in reframing circularity not just as a sustainability issue but as a business and economic imperative. Leaders in the machinery sector are pivoting to this mindset, recognizing the potential for growth and strategic differentiation. By broadening the perspective to value creation, we can unlock new opportunities and decouple GDP growth from resource consumption."

Meeting Evolving Customer Expectations

The machinery industry is witnessing a paradigm shift in customer expectations, driven by a growing demand for personalised products delivered at unprecedented speed. As highlighted in the Bain report, nearly 70% of customers now expect the same quality of products they received three years ago, but with shorter lead times.

Closed-loop PLM is emerging as the answer to these evolving customer demands, offering a streamlined approach to design, iteration, and validation. By harnessing the power of data collected in real-time throughout the product life cycle, companies can accelerate innovation, reduce time to market, and deliver highly customised solutions that resonate with customers.

Unlocking Value Through Closed-Loop PLM

The benefits of closed-loop PLM extend far beyond meeting customer expectations, encompassing cost efficiency, quality assurance, and operational excellence. Bain's research reveals that leading companies leveraging closed-loop PLM have reported significant improvements in on-time delivery and reductions in R&D costs.

One of the key advantages of closed-loop PLM lies in its ability to enhance parallel process development, enabling cross-functional teams to collaborate seamlessly and make data-driven decisions more quickly. Real-world success stories, such as Olbrich's experience with a PLM system, underscore the transformative impact of closed-loop PLM on efficiency and innovation.

Cost Efficiency and Quality Assurance

In addition to driving innovation and speed to market, closed-loop PLM offers tangible benefits in terms of cost efficiency and quality assurance. By providing better access to product data and enabling the reuse of designs, companies can reduce R&D costs and ensure higher-quality products.

The Bain report highlights the success of companies like Kampf, which have seen significant cost savings and productivity gains through the implementation of closed-loop PLM. By leveraging advanced product data management systems, companies can minimise errors, increase productivity, and gain a competitive edge in the market.

Navigating Implementation Challenges

While the benefits of closed-loop PLM are clear, implementing this transformative approach is not without its challenges. Companies must navigate complexities related to strategy alignment, organisational readiness, and technological infrastructure.

However, with the right approach, companies can overcome these challenges and unlock the full potential of closed-loop PLM. By adopting a cross-functional mindset, investing in employee upskilling, and leveraging advanced data analytics and technology solutions, companies can position themselves for success in an increasingly competitive marketplace.

Seizing the Opportunity

Closed-loop PLM represents a significant investment for machinery companies, but it also presents a tremendous opportunity for innovation and growth. As customer expectations continue to evolve and competition intensifies, companies that embrace closed-loop PLM stand poised to outpace their competitors and lead the industry into a new era of procurement excellence.

The transformative power of closed-loop PLM in the machinery industry cannot be overstated. By driving efficiency, accelerating innovation, and meeting evolving customer demands, closed-loop PLM is reshaping the landscape of procurement and positioning companies for sustained success in an increasingly dynamic market.

******

Make sure you check out the latest edition of Procurement Magazine and also sign up to our global conference series - Procurement & Supply Chain LIVE 2024

******

Procurement Magazine is a BizClik brand